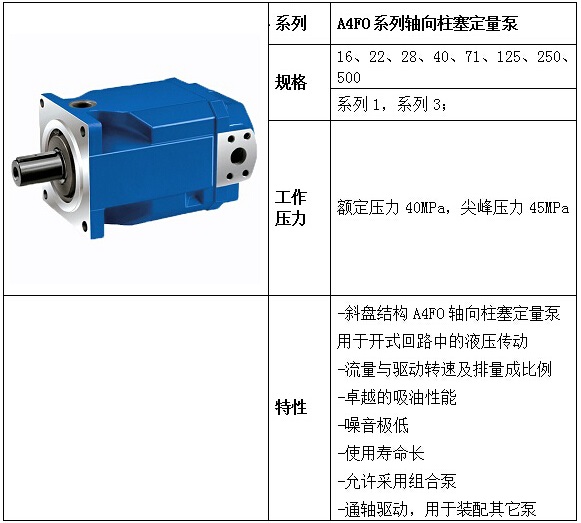

A4FO quantitative axial piston pump

safety instructions

When starting and during operation, the pump housing must be filled with hydraulic oil (fill into the housing cavity). Must start at low speed without load until the system is completely empty.

When parked for a long time, oil can be drained from the case through the working pipeline. When restarting, ensure that enough oil is injected into the shell.

The minimum suction pressure of port S must not drop below 0.8 bar.

Installation location

The axis is horizontal at the bottom. When installing on the oil tank, it is not allowed to adopt the installation position of "shaft level, suction port towards the bottom"!

Installation below the tank level

The pump position is below the lowest oil level in the tank (standard)

➔ Fill the axial piston pump before starting through the case drain port at the highest position

➔ Suggestion: Fill the suction line

➔ Run the pump at low speed (ignition speed) until the pump system is completely filled

➔ The minimum immersion depth of the suction line or the drain line in the fuel tank: 200 mm (relative to the lowest oil level in the fuel tank).

The installation position is higher than the oil tank level

Pumps installed at a position higher than the lowest oil level in the oil tank

➔ The installation position is lower than the oil tank level

➔ It is not allowed to adopt the installation positions of "shaft against the top" and "shaft level, suction port at the bottom" (when the pump is stopped, the pump casing drains oil through the suction line).

➔ Note:-Maximum allowable straw length hmax = 800 mm

-The minimum allowable pressure of port S (minimum suction pressure)